A Twin enabled Digital Industrial Platform

MIT Portugal 2023 Annual Conference

Content:

Vision

Although digital twin technologies have rapidly become a pervasive research topic, implementations are still sparse, with adoption rates not reaching 10% in most industries. Implementing the digital foundation required to leverage these technologies has been challenging for many organizations due to:

- the lack of a dominant design;

- the number of resources required to deploy and scale up infrastructure; and

- the constant need to compete in markets where not every firm is undergoing the burdens of transformation.

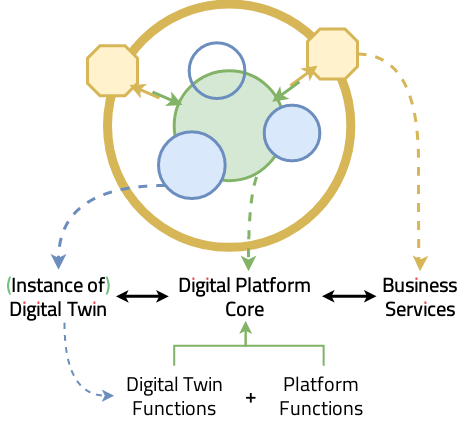

Focused on a vision that embraces digital twin technologies as the core architectural element for managing the physical and integrating the virtual industrial assets, we tackle these challenges by developing enterprise information systems that, although digital, become ever less virtual and drive forward the continuum between physical and virtual assets, required for the digital transformation in industrial environments.

Architecture & Design

Our vision for a Twin enabled Digital Industrial Platform stands on four design principles:

- Data Management

- Aggregate, structure, and provision historical data from the multiple product lifecycle stages of various working instances of digital twins;

- Leverage semantic technologies to answer the complex challenge of integrating data sources characterized by their heterogeneity in terms of (i) data and content types, (ii) time properties, and (iii) structure.

- Instance Management

- Provide the technical tools to enable the real-time management and orchestration of multiple instances of digital twins

- Manage simulations, analysis, and intelligence services to serve as the virtual counterpart to the physical products or services

- Ecosystem Management

- Support and facilitate the development of an ecosystem of users, customers, suppliers, and third-party platform complementors

- Provide tools and interfaces to abstract complexity and promote the generation of new services based on the industrial assets integrated through the multiple instances of digital twins into the platform

- Interface Management

- Integrate tools and mechanisms to ensure data sovereignty throughout all services and functionalities (core and complementor provided)

- Provide standard interfaces and boundary resources, such as APIs and SDKs, to facilitate access to platform services and the building of complementary platform solutions

Application in the TRF4.0 Project

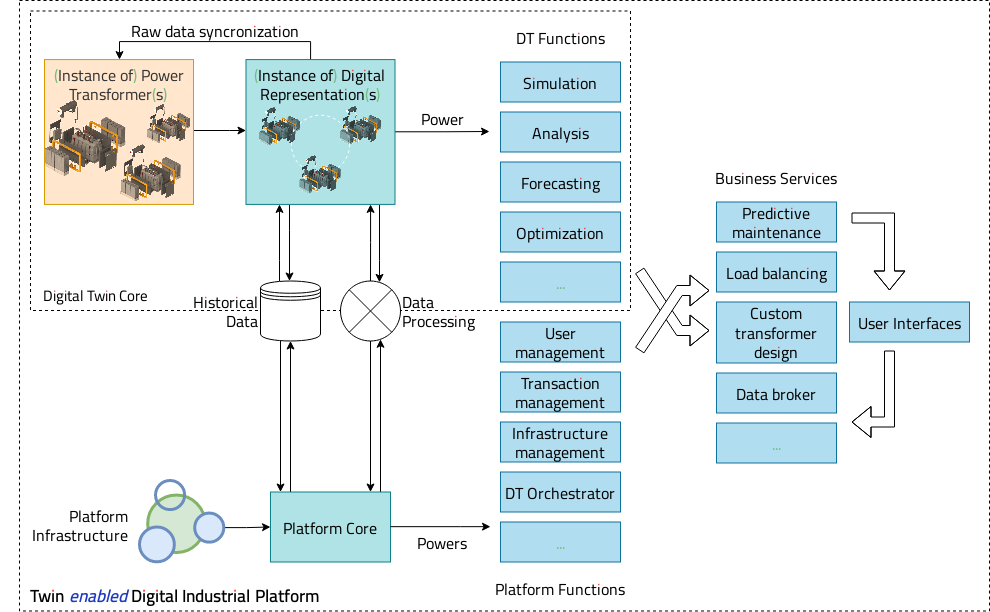

The TeDIP in the TRF4.0 Project sets up the (data and technical) infrastructure to offer services that streamline power transformer development and add value to the physical beyond its typical operation.

The developed infrastructure, which combines twin (cyber-physical) and platform (ecosystem and business) based functions and the knowledge captured during the power transformer lifecycle, can support tools and services such as the detection of design non-conformities based on operational insights, requirements, and constraints, simulate critical operating conditions, real-time monitor transformer performance, and provide insights for predictive maintenance and remaining useful life predictions based on operational parameters.

Related Work:

- A Vision for a Platform-based Digital-Twin Ecosystem

- A Digital Twin Platform-Based Approach to Product Lifecycle Management: Towards a Transformer 4.0

- Digital Platforms as Enablers of Smart Product-Service Systems

Poster

(click poster for full resolution PDF. ~5MB)